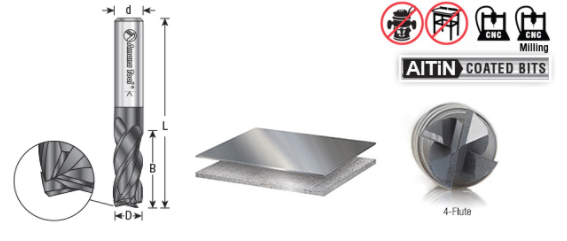

Amana - 51593 - 1/4" Steel Cutting Multi Helix

51593 - Steel Cutting Multi Helix (Solid Carbide, Square Bottom, Up-Cut)

- Shank: 1/4"

- Diameter: 1/4"

- Cutting Length: 5/8"

- Overall Length: 2-1/2"

- Flutes: 4 Flute Up-Cut

Amana Tool's variable helix tools are the superstars of carbide end mills for professionals and hobbyists alike. The variable helix eliminates harmonic chatter, so critical when surface finishes part dimension tolerances and tool life are of the utmost importance. Premium Aluminum Titanium Nitride (AlTiN) coating provides quantum increases in productivity either in terms of speed or longevity with or without coolant.

They are outstanding tools for peripheral milling and can take aggressive cuts along the full length of the overall flute length with no issues. They last much longer than general purpose end mills partly because they are coated partly because they dampen vibration which tends to break a sharp cutting edge down very quickly. For use with manual and automatic milling machines, as well as the most sophisticated CNC machines.

Excellent for cutting

- Stainless Steel

- Titanium

- Cast Iron

- Steel

- Cermet*

- Metal Composite Material (MCM)

AlTiN Coating

- Extra wear resistance

- Allows for faster feed and speed rates

- Cutting edge protected from wear

- Better chip evacuation

- Less heat build up

- Superior cutting quality and extended tool life

Warning: Inspect cut quality adjust feed and speed accordingly. Care should be taken to observe proper feeds and speeds according to the workpiece material to avoid damage.

Speed and Feed Rate

CNC running parameters based on 1 x Diameter depth per pass:

- RPM: 18,000

- Feed Rate: 50 IPM

- Chip Load per tooth: 0.0011"

- Ramp down Rate: 13 IPM