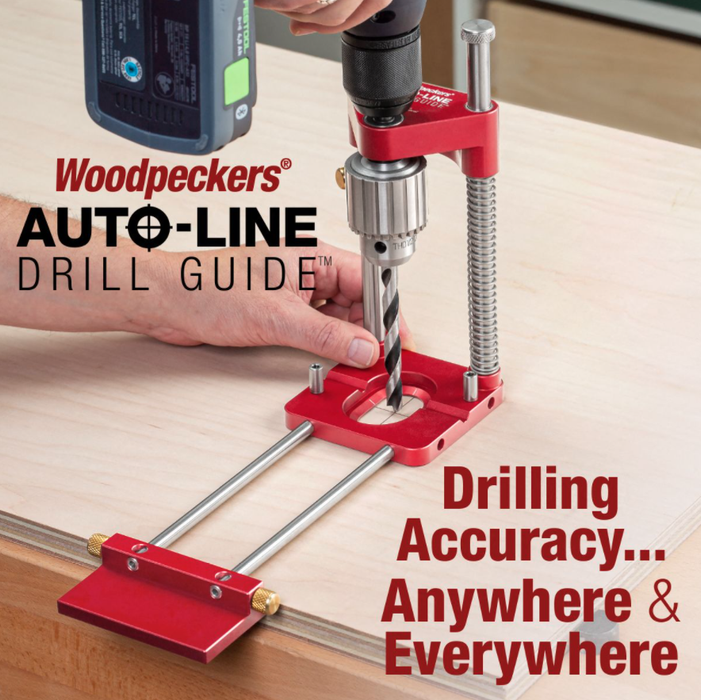

Auto-Line Drill Guide

Woodpeckers Accurate Drilling Guide

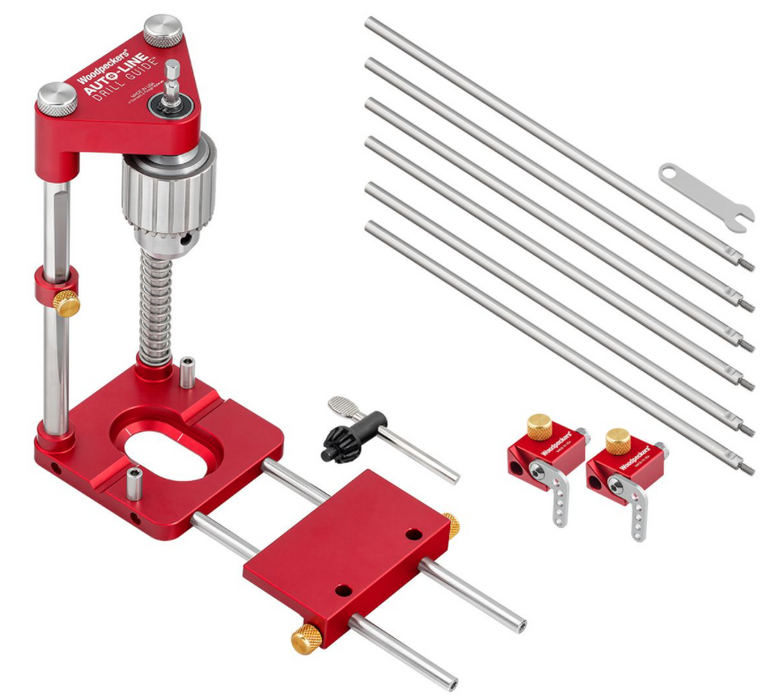

There are those among us who can pick up a drill, place it on workpiece and drill a straight hole. Then, there are the remaining 99.9% of us. A drill press solves the problem... as long as the piece you want to drill fits. But if you're not one of the 0.1% and you want a straight hole in the middle of a large piece of plywood, or in an installed cabinet, or in anything you can't get to your drill press (or you don't have a drill press), you want to keep reading. Introducing Woodpeckers Auto-Line Drll Guide. This new tool keeps your drill bit perfectly perpendicular while you drill, but it goes further. Woodpeckers added a versatile base and fence system that makes it simple to keep your hole locations right on target.

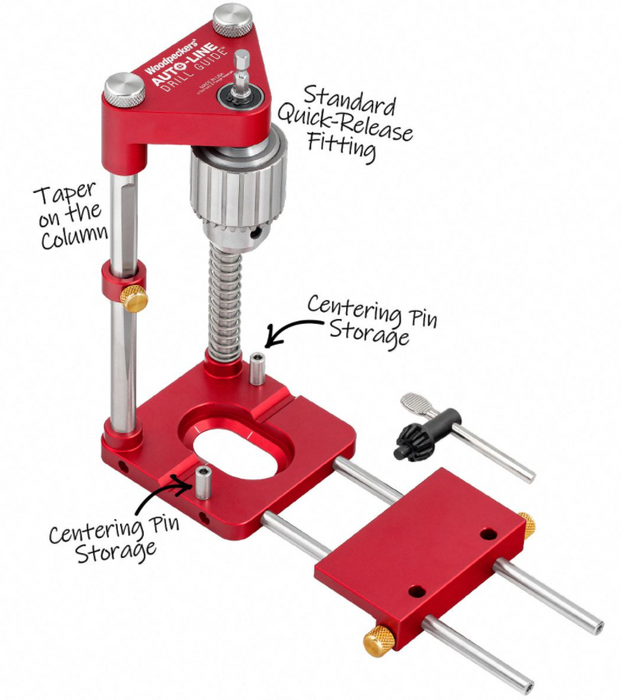

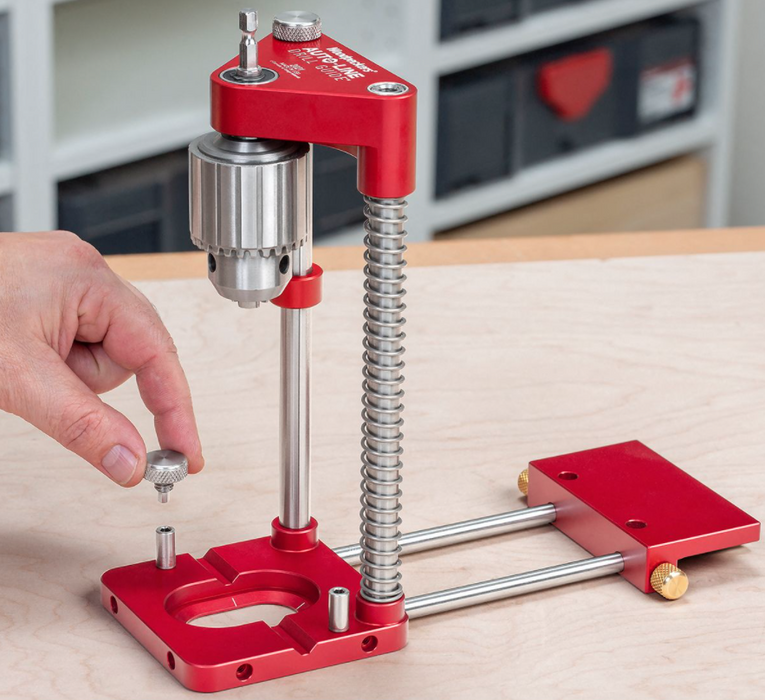

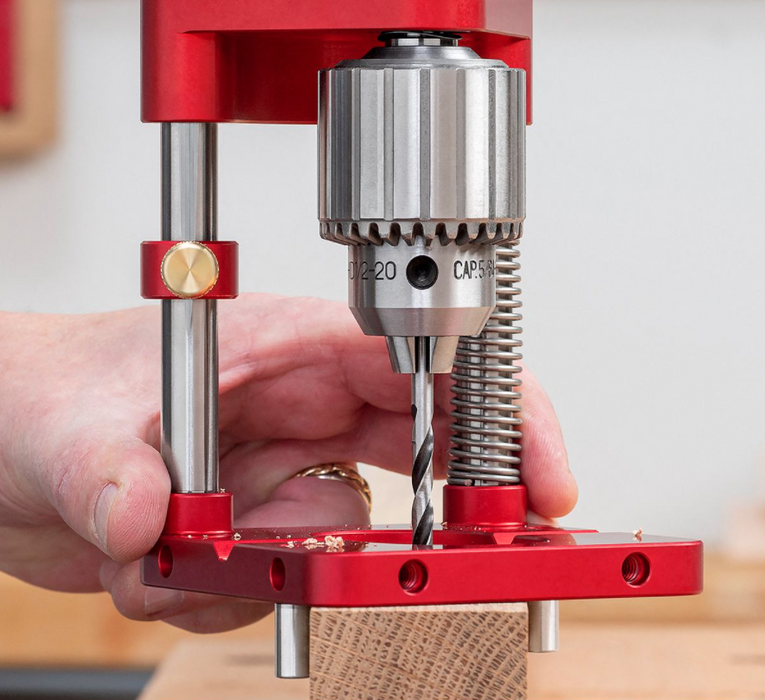

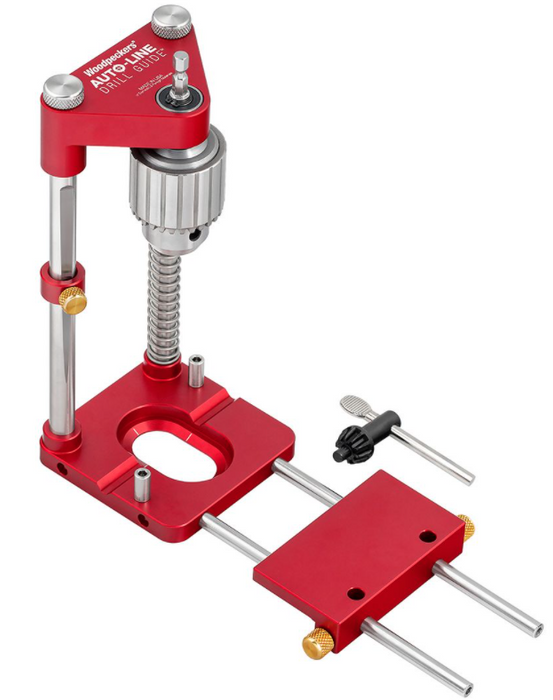

The Auto-Line starts with a high quality 1/2" chuck supported by a pair of sealed ball bearings. THe shaft end is a standard quick-release fitting that will fit any cordless or corded drill. The chuck carrier holds a pair of Teflon sleeves which ride on two stainless steel columns, keeping the chuck perfectly vertical while you drill. One column has a spring to help you control your cut and the other has an adjustable stop collar. Notice the stop collar column has a taper milled into it. The stop needs only fingertip pressure to hold position...it's nearly impossible to knock the stop out of position when the lock is tightened onto the taper.

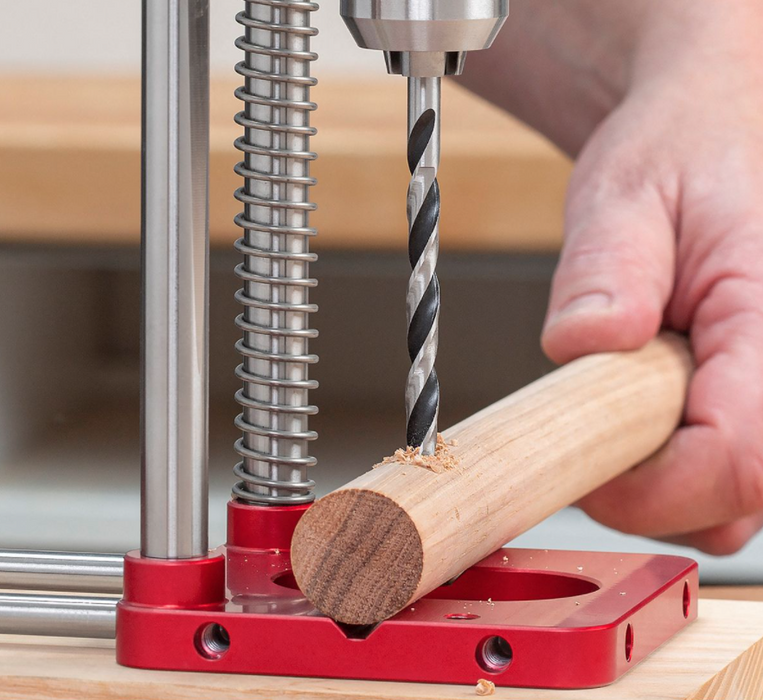

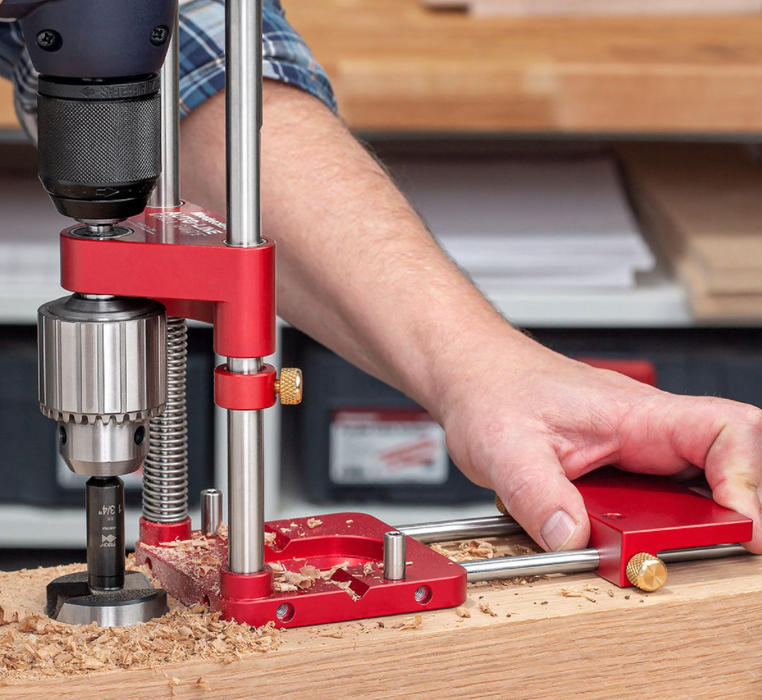

The base of the Auto-Line has laser engraved centerlines on the perimeter of the opening. Just align the bright white index marks with the witness marks on your stock for precise hole location. There's a vee-groove milled into the base to safely drill round stock. The opening in the base has a clearance for drills up to 3/4". When you need to drill holes larger than 3/4", simply remove the column caps, turn the chuck carrier around so it is outside the base and drill up to 2" holes.

When you need holes centeredon a baord, mount the centering pins in the base and rotate until one pin is tight against each side of the stock. Now your bit is perfectly centered. It works on stock up to 3-1/8" wide. The centering pins store conveniently right on the top of the base when they're not in use. We machined the Allen wrench to install the pins onto the bottom of the column caps... you'll never have to sort through that coffee can full of Allen wrenches to find the right one.

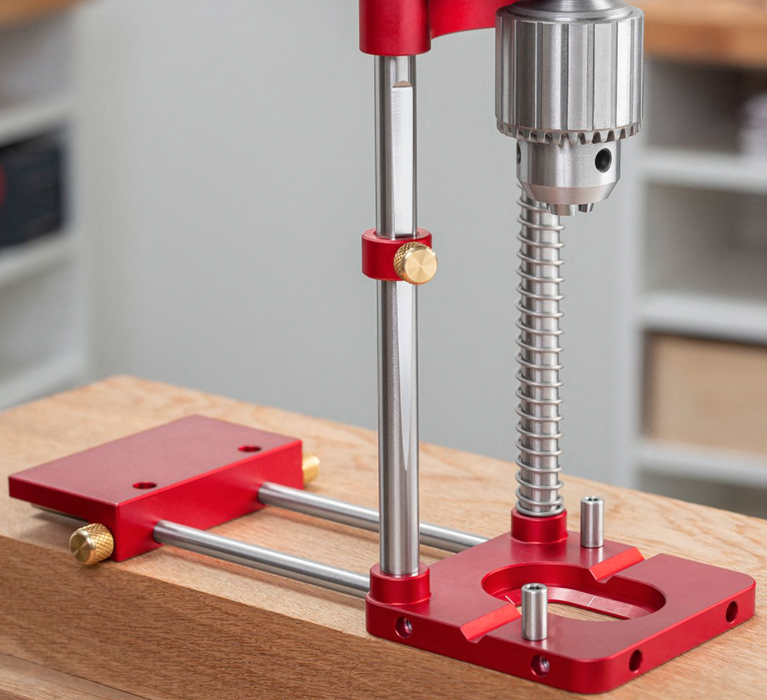

The versatile fence adjusts to the base along a pair of stainless-steel guide rods. As shown in the photos, the fence can slide under the base for working close to an edge, or turn it around to get the maximum distance. When you're working on a narrow edge, position the fence so the broad face provides extra support. And, when you're not using the fence at all, turn it so the thin edge provides an "outrigger" to improve stability. The base is drilled and tapped for the fence guide rods on all four edges...right, left, front or back...there's always a direction you can extend the fence. A set of optional fence guide rod extensions adds either 12" or 24" to the basic fence capaity of 7".

Like all Woodpeckers products, the Auto-Line Drill Guide is precisely machined and carefully inspected in their Strongsville, Ohio factory (just south of Cleveland).

Options

- Deluxe Set (ALDG-21-DEL) - Comes with the Auto-Line Drill Guide, 6 extension rods, 2 flip stops and wrench

- Auto-Line Drill Guide (ALDG-21) - 7" guide rods, fence and wrench

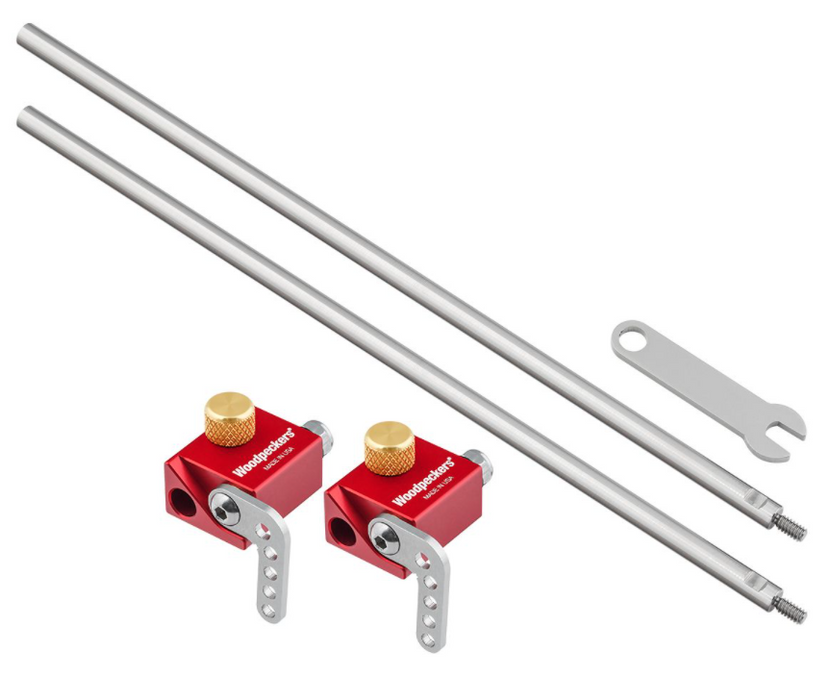

- Flip Stop Kit (ALDG-21-FSK) - Includes 2 flip stops, 2 extension rods and wrench

- 12"-24" Fence Guide Extension Rods (ALDG-EXT-21) - 4 x 12" extension rods and wrench

- Flip Stop (ALDG-21-FS) - 1 flip stop for Auto-Line Drill Guide