Laser cutting, a fascinating and versatile technology, has revolutionized the way we create and design in various fields. From intricate art projects to precise industrial components, the ability to cut and engrave materials with laser precision offers endless possibilities. KJP Select Hardwoods is here to help you find the best laser cutting materials for every project!

Whether you’re a seasoned artisan, a DIY enthusiast, or a curious explorer, understanding the diverse range of materials for laser cutting is essential to unlocking a universe of possibilities. We’ll go over a variety of laser cutter materials that will bring your projects to life at the click of a button. Read on to elevate your confidence in selecting laser safe materials!

The Best Materials for Laser Cutting

Laser cutting, a fascinating and versatile technology, has revolutionized the way we create and design in various fields. From intricate art projects to precise industrial components, the ability to cut and engrave materials with laser precision offers endless possibilities. KJP Select Hardwoods is here to help you find the best laser cutting materials for every project! Whether you’re a seasoned artisan, a DIY enthusiast, or a curious explorer, understanding the diverse range of materials for laser cutting is essential to unlocking a universe of possibilities. We'll go over a variety of laser cutter materials that will bring your projects to life at the click of a button. Read on to elevate your confidence in selecting laser safe materials!

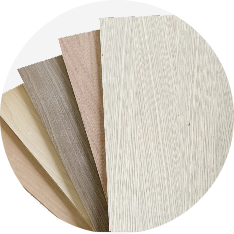

1. Wood & Plywood

Wood and plywood are incredibly versatile materials for laser cutting projects, offering a natural aesthetic and structural integrity. They are perfect for a wide range of applications, from intricate art pieces to functional objects. KJP Select Hardwoods specializes in providing a diverse selection of these materials.

Our inventory includes TruFlat® Laser Plywood, Baltic Birch, All-Birch, Ultra Thin Plywood, Craft Plywood, and much more suitable for all levels of laser cutting projects. Whether you’re a hobbyist or a professional, our collection ensures you can find the right wood type to bring your creative ideas to life.

Shop Plywood

2. Acrylic Sheets

Acrylic sheets are popular laser cutter materials known for their versatility and finish. They come in various colors and thicknesses, suitable for a wide range of applications. Acrylic, especially, is favored for its glass-like appearance and ability to create polished, professional-looking items. KJP Select Hardwoods offers a selection of acrylics catering to different project needs. Our selection provides an excellent starting point for both beginners and professionals looking to explore the creative potential of plastic and acrylic in laser cutting.

Shop Acrylic Sheets3. Fabric

Fabric is a newer yet increasingly popular material for laser cutting, offering unique opportunities for textile-based projects. Its application in laser cutting opens up possibilities for intricate designs and patterns that can be used in fashion, interior design, and art. With laser cutting, fabrics can be precisely cut and engraved, creating detailed and complex designs that would be challenging to achieve with traditional methods.

4. Leather

Leather is a premium laser cutting material, prized for its durability and luxurious appearance. It allows for high precision and detailed work, making it ideal for fashion accessories, decor, and personalized items. The laser cutting process on leather results in clean, burnished edges that enhance the product’s aesthetic.

5. Corian

Corian, a solid surface material known for its durability and sleek finish, is increasingly being used in laser cutting projects. Its non-porous nature makes it ideal for applications where hygiene is a priority, such as in kitchens and bathrooms. Corian can be precisely cut and engraved by lasers, allowing for intricate designs and detailed work. This versatility makes it suitable for a wide range of applications, from decorative art pieces to functional items.

6. Fiberglass

Fiberglass, a composite material made from fine glass fibers, is gaining traction in the field of laser cutting. Known for its strength, durability, and lightweight properties, fiberglass is used in a variety of applications, ranging from automotive parts to aerospace components. When it comes to laser cutting, fiberglass can be precisely cut and shaped, allowing for high levels of detail and complexity in design. However, working with fiberglass requires specific safety precautions due to the fine glass particles it can release. It’s essential to check with specialized suppliers or manufacturers for the availability of laser-suitable fiberglass and guidance on its safe handling and cutting.

For further info on laser cutting materials, you can refer to this laser cutter acceptable materials list for more options. Always be sure to reference your laser’s manual prior to cutting or engraving. Lastly, when purchasing laser cutting material, it’s important to take the bed size dimensions into account. We are happy to provide sizes that will fit your maximum bed size! Feel free to reach out for a custom quote. Our standard sizes will fit popular models from Glowforge, Aeon, Epilogue, and OMTech.

233 Reviews

233 Reviews

Our top selling plywood pre-cut for you!

Laser/CNC Grade: You can expect at least 1 face with no patches - often both!

Materials to Avoid in Laser Cutting

In laser cutting, certain materials should be avoided due to their potential health hazards or damaging effects on the equipment. We recommend you steer far away from trying to cut PVC, teflon, carbon fibers, vinyl, and artificial leathers on your laser. Many of these materials pose serious safety risks, including fire hazards and the release of toxic gasses.

Things to Consider When Buying Laser Cutting Materials

When shopping for the best laser cutting materials, you’ll want to first ask yourself what you intend on making.

- Do you want to create layered designs?

- Do you want to create something for exterior use?

- Do you intend on engraving as well?

Your specific project needs will help determine what is best for you.

If your goal is to create multi dimensional designs, we suggest creating with different thicknesses.

If you intend on having an engraved portion of your design in a different colour, you could consider two different options:

- The cost effective route would be to mask your material, engrave your design, and then do a paint fill. Remove the masking and then you have your design!

Creative Project Ideas for Beginners

For beginners in laser cutting, starting with simple yet creative projects is key to building skills and confidence. Consider projects like personalized keychains, coasters, or simple jewelry pieces from materials like thin wood or acrylic. These projects require basic cutting and can be easily customized with names, patterns, or simple images. Another idea is to create decorative items like wall art or photo frames, which offer more room for artistic expression while still being manageable for beginners.

Creative Project Ideas for Experts

For advanced laser cutting projects and techniques, enthusiasts can explore complex designs such as intricate 3D models, detailed architectural replicas, or sophisticated artwork. Techniques like layering materials, inlay work, or creating interlocking patterns add depth and complexity to projects. Advanced users might also experiment with combining laser cutting with other crafting methods, such as woodworking or electronics, for dynamic, multi-dimensional creations.

Laser Cutting Materials

Frequently Asked Questions

Do you ship your rough cut lumber?

Yes, absolutely. We are set up to ship our rough cut lumber worldwide.

I have an important project coming up and need my order quicker than the normal turnaround time. Can I pay a rush fee to get it sooner?

We can often accommodate rush orders. Please email or call to make arrangements with our fullfillment department.

What is the difference between rough cut lumber compared to milled lumber?

Rough Cut Lumber

Rough Cut lumber is ideal for those who enjoy working with machinery or hand tools to mill their own boards. We use this term to describe boards that require additional milling. Rough cut lumber has been run through the planer to show the grain however they have not been dressed. You will need to mill both faces and edges. Rough cut lumber is also available in specific lengths with varying widths.

S4S Lumber

Also known as surfaced or milled lumber, S4S lumber is ideal for those who aren’t equipped with the necessary tools to flatten and straighten boards. The term “surfaced” or “dressed” refers to a piece of wood that has been milled. To achieve the necessary dimensions, we select a larger board to work from. Both faces and edges are then surfaced so you can be assured that the board is flat and straight. These boards are available in specific sizes.